Learn about the Different Benefits of Rapid Prototyping

For many years, urethane casting and rapid prototyping contributed a lot of benefits to the manufacturing industry. Actually, the methods used by manufacturers in rapid prototyping has improved over the years and until now, they are still being used by a lot of companies worldwide.

Rapid prototyping is one of the methods used by manufacturers to create objects that will be analyzed and observed before they produce the final product of the company. Since manufacturers obtain many benefits in using this method, they are always considering this in manufacturing. Here are some of the popular benefits provided by rapid prototype to manufacturers around the globe.

Creating Better Designs for Products

As you can see, the design of a specific product will not be easily decided based on the drawings or illustrations made by the designers. The designs must be made into reality and it has to be created with a physical form so you can easily know if the design is good or not. If a physical form will be created based from the design and with the help of prototyping, the manufacturers can easily make improvements on its looks. The creation of these prototypes will be continuous until they successfully created the design that they want.

Keeping Track of the Design

Through the help of rapid prototyping, like what is mentioned earlier, the designers can track down all the changes and improvements on the design. They can take note of the changes made and create more improvements for the next prototype that they will be creating.

Fixing the Problems on Manufacturing

Prototyping can help prevent big problems on the company especially when a certain product has a lot of defects. All the defects of the products will be easily seen and corrected through the help of prototyping so these problems will be prevented even before the product is send to the market. It will be easier to pinpoint the problem on the product and they can easily find a solution to it and prevent the products from having problems and defects.

Save Money

Well, many experts already told a lot of people about how prototyping helps companies save a lot of money from products that will be replaced due to defects. Aside from these benefits, you can easily find some websites that will offer some valid information about the other benefits of rapid prototyping.

Always keep in mind that if you want to improve the products that you are selling on the market, you have to make use of rapid prototyping and consider all the benefits that it will offer you.

The Different Types of Rapid Prototyping

If your company is more on the manufacturing side, it is probably understandable if you know the importance of prototyping in the creation of plastic parts. Basically, during the research and development of a particular product, prototyping can really be a great help and it plays a very important role.

If your company is more on the manufacturing side, it is probably understandable if you know the importance of prototyping in the creation of plastic parts. Basically, during the research and development of a particular product, prototyping can really be a great help and it plays a very important role.

If a particular product is being mass produced, rapid prototype is important because damages and problems on the product are irreversible once they are already made. If you will look closely on the scenario, the company will surely waste a lot of time and products if they manufactured a product with a lot of defects. If they made 5,000 products with a defect, they have to do it again and produce another set to remove the defect on the products. This is a good reason why most of the manufacturers around the globe are considering urethane casting prototypes before they mass produce a specific product.

All the problems on the product can be resolved if the manufacturer will consider a rapid prototype before they mass produce the finish product. Actually, it will not be a problem to create a lot of prototypes especially if you want to prevent damages and other problems on the product before it is produced and sold to the public. This will surely save your company a lot of time and money since you do not need to worry about defects on the products. You can understand the benefits of rapid prototype by checking out some of the websites on the Internet.

Manufacturers around the globe are making use of the different rapid prototyping depending on their needs.

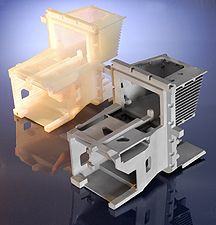

Stereolithography

This form of prototyping is making use of UV rays to solidify liquid acrylic polymer layer by layer until the prototype desired will be completed. This type of prototyping is actually made through the use of a machine known as VAT. This is quite popular to a lot of people because it is more accurate and faster when compared with the other types of prototyping.

Fused Deposition Modeling

This is a form of prototyping where CAD drawings are used and converted into physical parts to successfully create a prototype. Since the parts are created based on the drawing, the physical parts will be created almost immediately.

Selective Laser Sintering

This prototyping is a bit complicated since they make use of a heating process but they are preventing the product from melting to create a coherent mass. The prototype will be created through the use of a CAD program guided laser by fusing the powdered material.

Recent Comments